ABOUT US

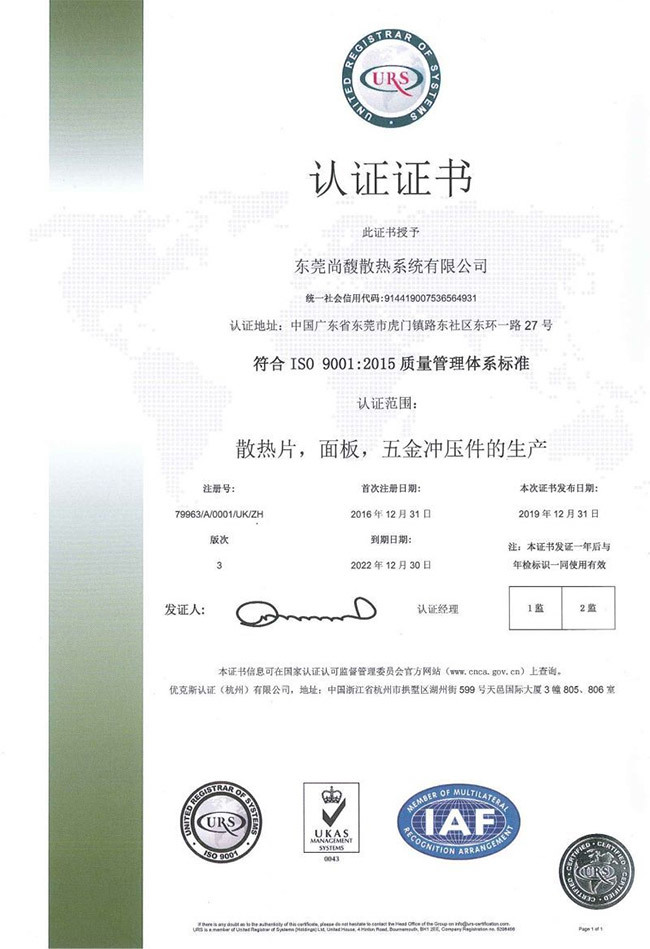

Dongguan Summit Thermal Systems Co., Ltd was established in Taiwan in 1989 and a manufacturing factory was established in Humen, Dongguan City in 1998. For over thirty years, it has been dedicated to producing radiators, sheet metal parts, machined metal parts, etc. in various industries. It is a company that integrates market development and customer service, product and technology research and development, and production and manufacturing services.

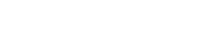

Summit Cooling has the ability to batch produce key components for thermal management and develop new processes, providing thermal management support for partners to achieve more perfect products. The company has fully passed ISO9001:2008; ISO14001:2004; TS16949 and other quality management system certifications serve North America, Europe, Japan, Australia, the Middle East, South America, Southeast Asia and other regions, providing excellent thermal management solutions and products for industrial automation equipment, medical equipment, lasers, energy, communication, electronic information, transportation and other industries. They have won the trust and recognition of world-renowned manufacturers such as ABB, Rockwell, Siemens, Schneider, Analog, Phillip, Yaskawa, and others.

Established in Taiwan

Deeply cultivate the field of heat dissipation

Company Floor Area

Equipment

development path

发展历程

development path

Qualifications and honors

ISO9001:2015 certification, ISO14001:2015 certification, awarded the titles of Rockwell Excellent Supplier and Enics Excellent Supplier

IS09001:2015

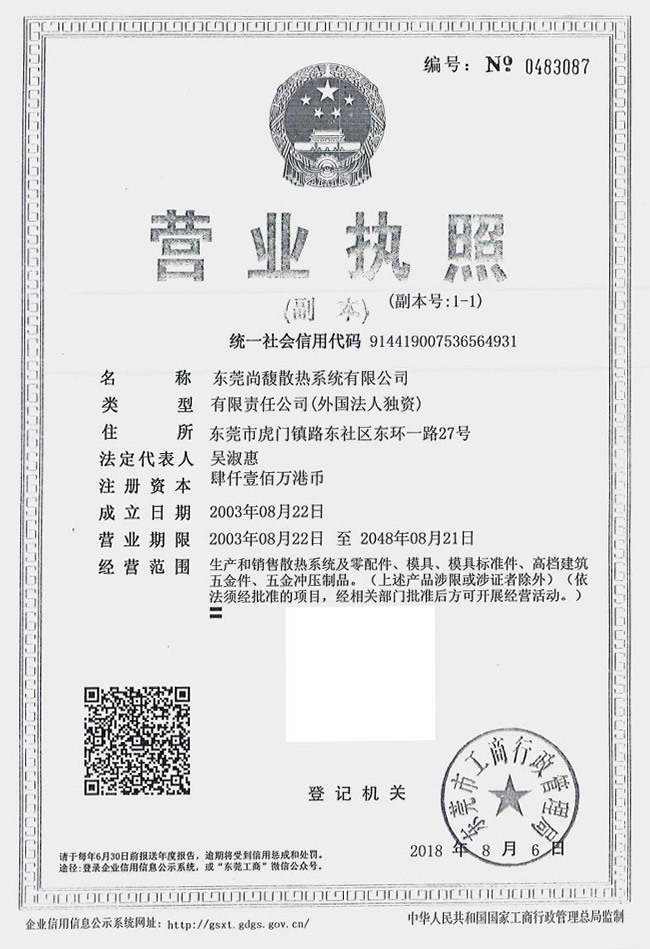

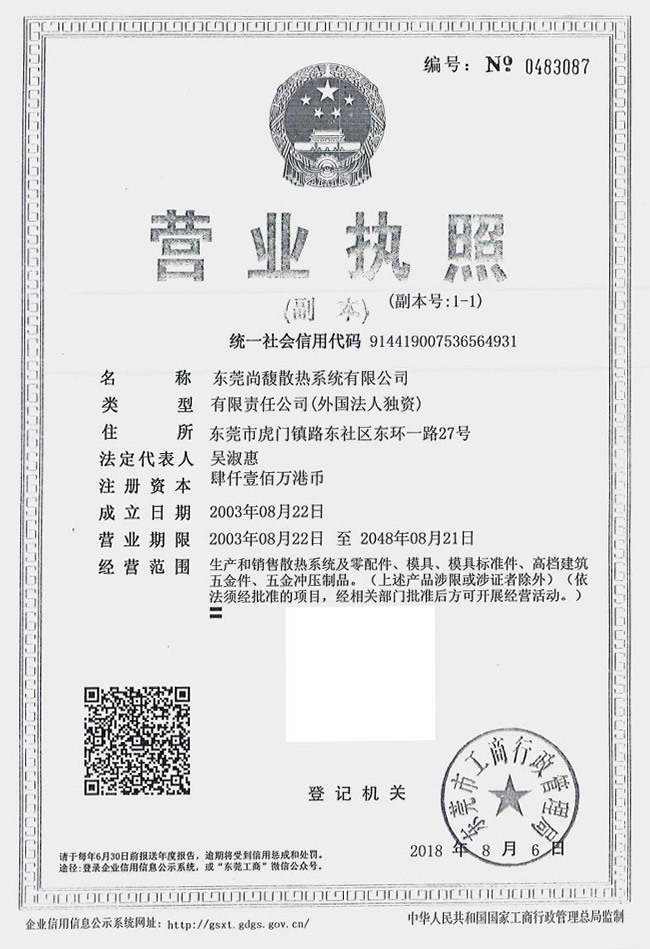

Business License 04

Business License 03

Business License 01

social responsibility

For the past thirty years, while continuously developing, Summit has also deeply realized that enterprises are also members of society. In addition to focusing on the growth and activities of enterprises, they also fulfill their social responsibilities through activities such as environmental protection and creating a reasonable workplace

01

Continuously improve employee welfare and create a good working environment.

02

Implement resource classification and recycling throughout the site to reduce the total amount of waste. By improving and optimizing internal systems, paperless operation is achieved to reduce paper consumption and indirectly reduce environmental damage.

03

Passed ISO 14001 environmental certification.

04

Continuously improve employee welfare and create a good working environment.

05

Continuously improve employee welfare and create a good working environment.

cooperative partner

Won the trust and recognition of world-renowned manufacturers such as ABB, Rockwell, Siemens, Schneider, Analog, Phillip, Yaskawa, etc